Internet of Things. Cyber-Physical Model of AI

The Internet of Things improves the integration of the virtual and physical worlds. It is an important underlying technology in areas such as smart homes, smart cities, smart transport systems and smart grids. IoT applications include environmental monitoring, infrastructure monitoring, building and infrastructure automation, activity recognition, and behavioral monitoring. The "things" that form the Internet of Things can be diverse physical objects such as cars equipped with sensors, medical implants, household appliances, smart watches, and other wearable devices, thermostats, and ventilation system controllers.

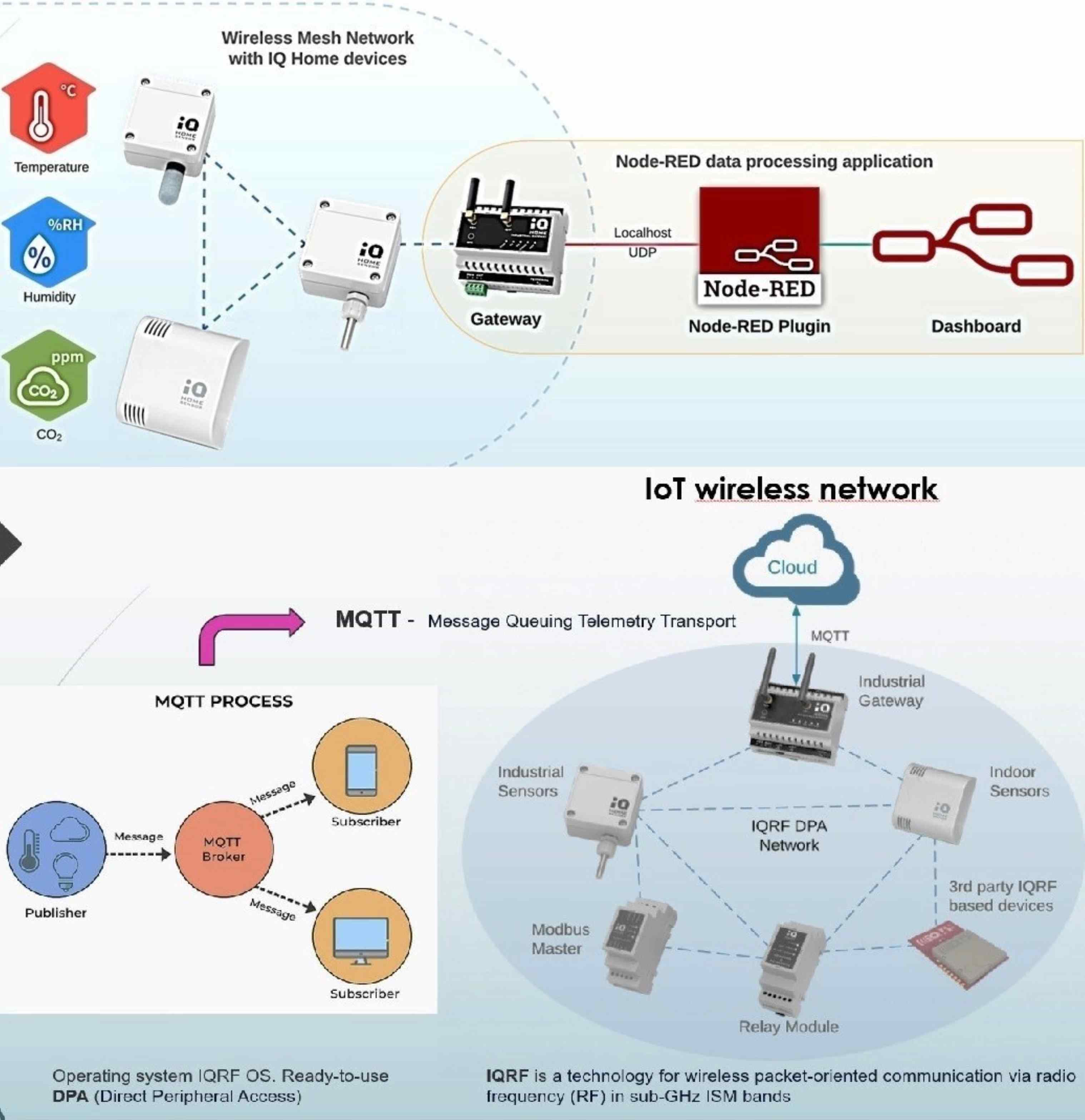

The current vision of the Internet of Things has evolved from the convergence of several technologies. It relies on traditional disciplines such as wireless sensor networks, embedded systems, and control and automation systems (including manufacturing automation, homes, and buildings).

In the 1970s, as computers ceased to be a separate and unique product, mass automation began in two largely independent directions. One direction is the automation of business processes, referred to as information technology (IT). The other is the automation of technological processes, which began to be referred to as operational technologies (OT) or the Industrial Internet of Things (IIoT).

It is crucial to understand that IT focuses on data rather than information, making "data technology" a more accurate term. IT encompasses computers, storage solutions, and networks for the creation, processing, storage, security, and transfer of all forms of electronic data. In contrast, OT (IIoT) consists of hardware and software specifically designed for controlling and managing physical processes.

The IoT architecture typically includes the following layers:

Device layer. This is the lowest layer, including the physical devices and sensors that make up the IoT network.

Network layer - this layer is responsible for connecting devices and ensuring communication between them.

Data management layer - this layer includes systems for storing, processing and analyzing data generated by IoT devices.

Application layer. This is the highest level, including applications and services that use data generated by IoT devices to create a model for object automation.

Security level. This layer provides security mechanisms to protect the IoT network and data from unauthorized access and threats.

The industrial Internet of Things (IIoT) has become an integral part of almost all industrial systems around the world. IIoT is designed to collect and analyze huge amounts of data to help find ways to optimize TP and RP hardware and improve efficiency.

In the industrial Internet of Things, the functioning of IIoT systems is largely dependent on sensors and actuators. Without them, the whole concept of IIoT automation will fall apart.

Sensors are used to control processes and equipment and provide data on how systems operate. Sensors monitor physical activity and warn of changes in the operation of the equipment or its environment. Actuators receive signals from control modules to perform physical actions, such as controlling a robot arm.

When connected to enterprise asset management software (EAM, Enterprise Asset Management, such as Manager Plus), these devices can help predict hardware failures and improve equipment reliability.

Intelligent technologies, expert systems and artificial intelligence are the main trend in the development of technological progress in the 21st century, opening up new opportunities in the field of chemistry, biology, ecology, medicine, information technology, industry, agriculture, in measuring and controlling quality compliance, in optimizing TP and other processes, in testing and management using information and technological advances.

Intelligent technologies are increasingly being introduced into technical and biosystems. The adaptation principle ensures manufacturability and continuous optimal control of processes at facilities with non-stationary and non-deterministic parameters under conditions of stochastic disturbances. These features are characteristic of most biological and agricultural objects, processes and systems because plants and animals dominate there, as well as food bacteria during their processing, storage and selection.

The development of intelligent technologies is based on the biological objects' determination of analogy, modeling, electronics of human organs, in biochemical, nanomolecular and other phenomenological imitations, structural modeling and research of adaptation possibilities for a specific automation object or technological process.

However, we need artificial intelligence (AI) technology only when making decisions in conditions of uncertainty and unpredictability of events, based on the use of behavior patterns (patterns) becomes impossible based on algorithms, and then the necessary component of making an expedient decision is intelligence - as an alternative to the algorithm. To remove or reduce uncertainty, the so-called "deep machine learning" with a teacher (deep learning), with a previously known result that "intelligence" is essentially not. The machine has neither associative thinking, nor creative abilities, nor consciousness, and there is no "intelligence" there and, in principle, cannot be. Therefore, the use of "artificial" intelligence in terminology here will be considered conditional.

So, artificial intelligence takes on the role of a kind of intelligent interface that interprets and offers the user, rather than a vague set of information, but ready to use, targeted and, therefore, useful knowledge and considered solutions, suggestions and recommendations.

Internet of Things (IoT). The Cyber-Physical System (CPS) is a system that provides close communication and coordination between virtual computing and real-world physical resources. The scope of CPS covers robotics, transportation, energy, industrial process automation, and large infrastructures. Cyber ; ; Physical Social Systems (CPSS) combines the physical, cyber and social worlds, provides real-time interaction between them.

A technological singularity is a hypothetical moment in the future when technological development essentially becomes uncontrollable and irreversible, which causes a radical change (singularity) in the essence of man and civilization as a whole. According to one of the most popular versions, the technological singularity is caused by an "intellectual explosion" (this concept was put forward by the British mathematician and cosmologist Irving Good).

An updated intelligent agent (for example, a computer with powerful artificial intelligence) can eventually enter the cycle of self-improvement as an act of "uncontrolled reaction" and each new generation of "artificial intelligence" will appear faster and faster, creating a kind of "intellectual explosion" product. Ultimately, the machine independently creates a super-intelligence, nominally superior to human intelligence. For the first time, the concept of "singularity" was mentioned in a technological context by the American mathematician John von Neumann.

Industrial revolution. There are a large number of theories and concepts about what discoveries and events in different periods led to radical changes in society, and for this reason, can be considered revolutions. The most famous of the theories says that first there was an agricultural (agrarian), then an industrial revolution, followed, and now there is a technological (information) revolution.

Общую картину хорошо описывает т. н. «четвертая промышленная революция», которая более известна как (Индустрия 4.0). Революция получила это название благодаря идее бизнесменов, политиков и ученых о том , что повысить конкурентоспособность индустрии можно за счет более глубокой интеграции киберфизических систем в производственные процессы.

CPS— это широкое понятие, которое обычно используется как термин «Интернет вещей» (IoT). Концепция тезиса «Industrie 4.0» призвана двигаться в сторону интеграции уже не на стороне потребителя, а на стороне производителя. В 2014 году в Европе и в США была создана некоммерческая организация промышленного Интернета, в состав учредителей которой вошли такие крупные компании, как General Electric, AT&T, IBM и Intel.

According to another popular theory, the fifth is already underway - the information revolution: the appearance of writing is considered the first, printing in the middle of the 16th century - the second. The third information revolution is associated with the introduction of electricity, the fourth information revolution of the 70s of the last century is associated with the introduction of microprocessors and computers into control systems. Thanks to this innovation, the transfer of information from a mechanical to an electronic (digital) environment began. The fifth revolution began in the 80s of the last century. The symbol of the fifth revolution is the Internet, the globalization of information.

There are also many supporters of the concept that humanity is at the stage of the third technological revolution. The first revolutionary event is the appearance of a steam engine, the second is the invention of electricity and achievements in the field of chemistry, especially in petrochemistry, the third is the invention of a microprocessor.

Experts predict that the so-called "technological singularity" will begin in the middle of this century. Simply put, the whole Earth will turn into a huge computer. The move towards an information society has also led to the globalization of all other types of human resources: financial, transport, industrial, etc., while creating new business technologies and opportunities.

At the same time, Industry 4.0 raises concerns that cyberphysical systems, the Internet of Things, smart factories and industrial robots of recent generations will occupy more and more human work. Unlike the third industrial revolution, when automation became widespread in the production of equipment, the fourth revolution is designed to achieve mutual communication without human interference in everyday processes. In some plants, for example, at Siemens, almost all employees are already engaged only in machine and computer monitoring.

With the spread of Industry 4.0, many professions and types of business are expected to disappear, new professions will appear and business will be increasingly transferred to the virtual and cyber-physical environment, IoT, smart factories and smart cities, new financial and business technologies, new trends among consumers (protection of interests and rights). At the same time, robotization, computerization and digitalization promise social problems, as well as new security problems such as cybercrime, especially in the financial sector. Although changes happen very quickly, they are not chaotic, but obey certain patterns, so they are, first of all, well predictable. You just need to be prepared for the upcoming changes.

Humanity gets a chance to get rid of phobias, for example, "is the door closed at home?" or "Is the iron turned off at home?" because there will be operational information about this on the smartphone. It is clear that if the fire hazardous device is not turned off, then anything can happen. You can control and edit the process from anywhere in the city and the world. The tracking system of the "Internet of Things" recognizes the faces of all people who passed by your house, or who stood near the door of your apartment, and when the same face appears again, the "Internet of Things" will compare it with the police database. Just in case... A refrigerator with a camera and a smart set of sensors will inform you about the expiration date of products, and that you have run out of your favorite products and will help you order the missing goods in the store. A smart vacuum cleaner will send a message when it finds a lost expensive piece of jewelry under the sofa.

The current vision of the "Internet of Things" has evolved due to the convergence of many technologies, including wireless communications, smart sensors, gadgets, embedded devices and machine learning technology. Therefore, the Internet of Things is an interdisciplinary technology based on such traditional disciplines as wireless sensor networks, embedded systems, control and automation systems (including houses and buildings).

Subtleties of terminology. How correct is the term "Internet of Things" (IoT) and what accompanied its appearance? IoT is not the Internet, but just PaaS? What are IaaS, PaaS, SaaS? IaaS - (Infrastructure as a Service) - infrastructure as a service: virtual servers and virtual network. The client can install any software and application. PaaS - (Platform as a Service) - Platform as a service, for example, a web server or database; client manages applications, service provider manages operating system. SaaS - (Software as a Service) - software as a service, for example, e-mail or other office applications. The client uses the application and the basic application settings are controlled by the service provider.

In the seventies of the last century, starting from the moment when computers were no longer a separate and unique product, mass automation began in two practically independent directions. One of them is the automation of business processes, which we call information technology (IT).

Another is the automation of technological processes, this direction, unlike IT, began to be called operational technologies (OT, Operational Technology). It is important to clarify that IT is not dealing with information, but with data, so it would be more correct to call it "data technology." IT integrates computers, storage systems and networks with the creation, processing, storage, security and exchange of any type of electronic data. OT is also a set of hardware and software, but designed to monitor and control physical processes.

Previously, in the automation industry, popular terms were ACS "automated control systems" and ACS (automated process control systems). For more than forty years, IT and OT have developed independently and during this time have acquired characteristics that significantly distinguish them. But in the second decade of the 21st century, under the influence of several factors, including the sensory revolution, the development of network technologies, cloud computing, big data analysis and other modern trends, the IT/OT convergence process began, combining two approaches of data orientation and events in the physical world, i.e. a physical control environment has formed.

Industrial control systems. Industrial control system (ICS) is a collective term used to describe various types of control systems and associated instrumentation that include devices, systems, networks, and controls used to control and/or automate industrial processes. Depending on the industry, each APCS functions differently and is designed for effective electronic task management. Today, the devices and protocols used in ICS are used in almost all industrial sectors and critical infrastructure, such as manufacturing, transport, energy, water treatment, etc.

There are several types of ICS, the most common of which are Supervisory Control and Data Acquisition - SCADA and Distributed Control Systems (DCS). Local operations are often controlled by so-called field devices, which receive control commands from remote stations.

In the long term, we can expect the emergence of a single whole, consisting of traditional data-driven technologies, industrial control systems (ICS) and supervisory control and data acquisition systems (SCADA). Ultimately it will be cyber-physical systems or even social cyber-physical systems.

The Internet of Things (IoT) is a functional connection of physical devices. The devices that make up the "Internet of Things" (also called "smart devices" or "connected devices") are equipped with sensors, actuators and communications. The Internet of Things allows you to remotely receive information about various objects equipped with sensors, as well as remotely manage these objects using the existing network infrastructure, including the Internet.

The Internet of Things Global Standards Initiative (IoT GSI) defines the "Internet of Things" as a global information society infrastructure offering advanced services by connecting (physical and virtual) to existing and developing ones, and also includes issues based on information and communication technology compatibility. If there is no need to use the Internet, then objects can interact with each other using other technologies.

The Internet of Things improves the integration of the virtual and physical worlds. It is an important underlying technology in areas such as smart homes, smart cities, smart transport systems, and smart grid electricity. Examples of IoT applications include environmental monitoring, infrastructure monitoring, infrastructure construction and automation, activity recognition, and behavior monitoring. "Things" that form the "Internet of Things" can be a variety of physical objects, for example, cars equipped with sensors, medical implants, household appliances, smart watches and other wearable devices, thermostats, ventilation system controllers, etc.

The Internet of Things consists of loosely connected disparate networks, each of which is deployed to solve its specific tasks. For example, in modern cars, several networks operate simultaneously: one controls the operation of the engine, the other controls the safety systems, the third maintains communication, etc. Many networks are also installed in office and residential buildings to control heating, ventilation, air conditioning, telephone communications, security, and lighting.

As the Internet of Things develops, these and many other networks will connect and receive more and more security, analytics and management capabilities. Thus, the "Internet of Things" is a network of networks consisting of uniquely identifiable objects ("things") and capable of interacting with each other without human intervention.

The global embedded intelligent systems market is growing, driven by growing demand for portable computing devices and embedded systems. Other main growth drivers in recent years are the trend towards production automation, the constant development of complex computerization and the widespread use of the Internet of Things.

The main models with which IoT will be implemented soon. The first model is "compliance control." Compliance Control is a management and control system in the company related to risks of non-compliance with the requirements of legislation, regulatory documents, rules and standards of supervisory authorities, codes of conduct, other regulatory documents of the company. Compliance with standards, norms and requirements of regulatory organizations is an important prerequisite for doing business, but they do not bring direct economic benefits to companies, despite significant costs. In the context of this situation, the Internet of Things has huge potential to reduce costs in this area.

The second implementation model is preventive and preventive control: the "Internet of Things" allows you to timely identify the prerequisites for emergencies and reduced equipment efficiency. With the Internet of Things, you can remotely monitor real-time and online hardware performance.

The third model is remote diagnostics. IoT sensors can be used to diagnose the devices in which they are installed and automatically respond to changes in their status, properties and parameters.

The fourth model is transaction control. With IoT, you can monitor the chain of technological activity, control the movement of any devices and automatically track their properties in real time. This allows you to get rid of fraud, theft and uncontrolled losses, increase the efficiency of controlled objects on which "smart" sensors are installed, and achieve predictability of their operation.

The fifth model is automation of operations. The introduction of the "Internet of Things" allows you to automate repetitive actions, increase work efficiency, quality of recreation, as well as consumer and customer satisfaction. The advantage of such intelligent IoT tools is manifested not only in simplifying daily activities, but also contributes to the implementation of goods and services by automating the specific habits of users.

The modern concept of the "Internet of Things" means that all modern devices, regardless of platform, should be able to work together with other devices and services, forming a single interconnected ecosystem in which "things" are no longer separate elements. This approach is one of the main reasons for the transformation of the embedded market. Today, the development of the "Internet of Things" is moving towards building such intelligent systems (sensors, machines, mechanisms, devices, etc.), combined into one global computer network to obtain, process data and increase production efficiency (in the industrial sphere), provide comfort, convenience for users and food safety (in the field of protection of interests and consumer rights).

The implementation of such intelligent systems requires the coordinated work of participants from several areas, including simultaneously as suppliers of components (all processors, microprocessors, controllers, sensors, etc.) and end products (consumer electronics, industrial equipment, cars, airplanes... the list is truly unlimited), and software manufacturers who can customize all these embedded systems for individual customers by connecting components to the "clouds" and ensuring their interaction with other infrastructure elements of the system.

It is important to note that IoT existed already in the mid-90s. Integrated Systems Inc (ISI) has proposed the idea of ; ; Embedded Internet. Then it seemed naively that for communication between things it was enough to install the operating system pSOS, developed by ISI, into the built-in processor. (Portable Software On Silicon is a real-time operating system (RTOS) created in 1982 by Alfred Chao. Life has shown that the problem is much more complicated. Recently, a new term "Web of Things" (WoT) has appeared, which more closely corresponds to the concept of the "Internet of Things." Now the academic community is actively involved in the development of WoT.

The W3C consortium has created a working group on Web of Things issues, work is underway to develop standards, but the complexity and variety of devices (things) cannot be compared with texts. Accordingly, standardization of device interaction is many orders of magnitude more complicated than the case of text standardization. These works will take several years.

The rapid growth of the embedded intelligent systems market is largely due to the rapid development of the Internet of Things. More than 30 billion devices are expected to be connected to the global Internet of Things as early as 2025. The evolutionary boom of today's digital society will be based on technological innovations such as cloud computing and the Internet of Things. As a result, we will be surrounded by countless interconnected digital systems and innovations such as self-driving cars, cryptocurrencies and interconnected medical implants.

With the development of digital technologies, expert systems and artificial intelligence are becoming an increasingly serious problem. In general, the advantages of the "Internet of Things" speak for themselves, but its use does not eliminate real cybersecurity threats. Among the respondents, 84% of companies that already use Internet of Things solutions faced cybersecurity problems. More than half of Internet of Things users consider external cyber attacks to be the main obstacle to the introduction of this technology.

Свидетельство о публикации №224051601702